1. परिचय

This manual provides essential instructions for the safe and efficient operation, setup, maintenance, and troubleshooting of your OMTech 100W CO2 Laser Engraver. Please read this manual thoroughly before operating the machine to ensure proper usage and to prevent damage or injury. Retain this manual for future reference.

The OMTech 100W CO2 Laser Engraver is designed for precision engraving and cutting across a variety of materials, including wood, glass, and acrylic. It features a 28"x20" workspace, four-way pass-through doors, autofocus capability, and integrated air assist.

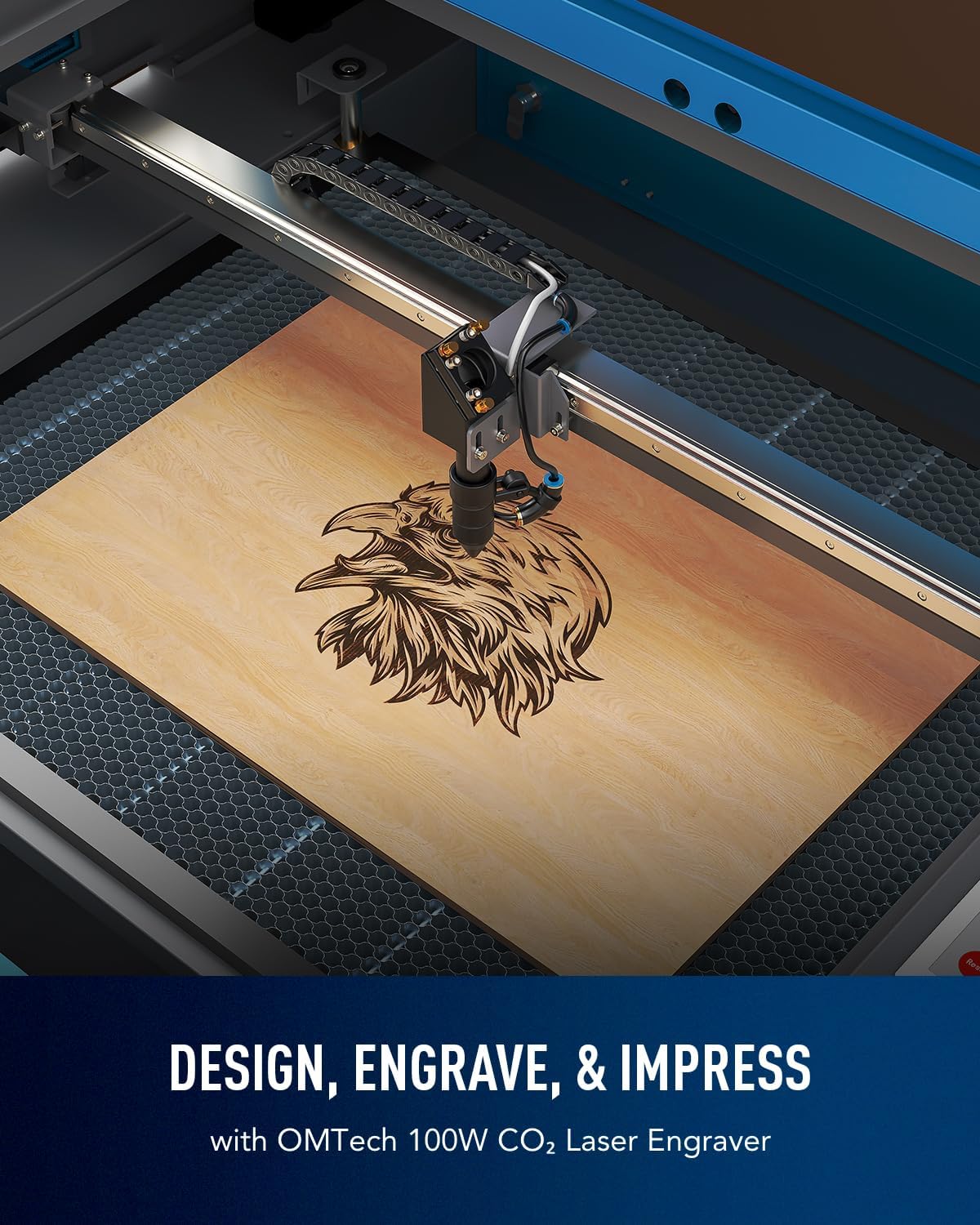

Image 1.1: The OMTech 100W CO2 Laser Engraver, a large blue and grey machine with a transparent lid open, showcasing the internal laser head and work area.

2. सुरक्षितता माहिती

Operating a laser engraver involves potential hazards. Adhere to all safety guidelines to prevent injury or damage to the equipment.

- लेसर रेडिएशन: This product is a Class 2 laser device with 0.827 mW output power. Never look directly into the laser beam or at reflections. Always wear appropriate laser safety glasses.

- वायुवीजन: Ensure adequate ventilation to remove smoke, fumes, and particulate matter generated during operation. Connect the machine to an external exhaust system.

- आगीचा धोका: Certain materials are flammable when exposed to a laser. Always supervise the machine during operation. Keep a fire extinguisher nearby.

- विद्युत सुरक्षा: मशीन योग्यरित्या ग्राउंड केलेले आहे याची खात्री करा. ओल्या हातांनी किंवा डब्यात चालवू नका.amp conditions. Disconnect power before performing maintenance.

- साहित्य सुसंगतता: Only engrave or cut materials approved for CO2 lasers. Avoid materials that produce toxic fumes or are highly reflective.

- आपत्कालीन थांबा: आपत्कालीन स्टॉप बटणाचे स्थान आणि ऑपरेशन जाणून घ्या.

3. पॅकेज सामग्री

अनपॅक करताना सर्व घटक उपस्थित आहेत याची खात्री करा:

- OMTech 100W CO2 Laser Engraver Unit

- LightBurn Software License (if included with purchase)

- Water Pump for cooling system

- Air Assist Compressor

- एक्झॉस्ट फॅन आणि डक्टिंग

- USB Cable, Ethernet Cable

- पॉवर केबल

- Tool Kit and Accessories

- वापरकर्ता मॅन्युअल आणि दस्तऐवजीकरण

4. सेटअप

१. अनपॅकिंग आणि प्लेसमेंट

Carefully remove the engraver from its packaging. Place the machine on a stable, level surface capable of supporting its weight (approximately 251 lb.). Ensure sufficient clearance around the machine for ventilation and access to the pass-through doors.

4.2. Connecting Cooling System

The CO2 laser tube requires water cooling. Connect the provided water pump to the designated inlet and outlet ports on the machine. Fill the water reservoir with distilled water. Ensure the water pump is submerged and operating correctly before powering on the laser.

4.3. Connecting Air Assist

Connect the air assist compressor to the machine's air inlet. The air assist system helps to clear debris from the laser's path and reduce scorching during cutting and engraving.

4.4. Exhaust System Installation

Attach the exhaust fan and ducting to the machine's exhaust port. Route the ducting to an outdoor vent or a suitable filtration system to safely remove smoke and fumes from the workspace.

4.5. विद्युत जोडणी

Connect the power cable to the machine and a grounded electrical outlet. Ensure the power supply matches the machine's requirements.

4.6. Software Installation (LightBurn)

Install the LightBurn software on your computer. Follow the instructions provided with your LightBurn license for installation and activation. Connect the engraver to your computer via USB or Ethernet cable.

Image 4.1: A computer screen displaying the LightBurn software interface, used for designing and controlling laser engraving and cutting operations.

5. ऑपरेशन

5.1. पॉवरिंग चालू

Ensure all connections (power, water, air, exhaust) are secure. Turn on the main power switch on the machine. Allow the water cooling system to circulate before proceeding.

३.१. साहित्य लोड करणे

Open the machine lid and place your material onto the workbed. Ensure the material is flat and securely positioned. For larger materials, utilize the four-way pass-through doors.

5.3. Autofocus Function

The machine features an autofocus function. Position the laser head over the material and activate the autofocus. The laser head will automatically adjust to the optimal focal distance for your material, ensuring precise engraving and cutting.

प्रतिमा २: जवळून पाहिलेला फोटो view of the laser head with a red dot indicating the laser's position, performing an automatic focus adjustment on a piece of material.

5.4. Using LightBurn Software

Create or import your design in LightBurn. Configure the appropriate laser settings (power, speed, passes) based on your material and desired outcome. Preview the job to ensure correct placement and scale.

5.5. Engraving and Cutting Process

Close the machine lid. Initiate the job from LightBurn. The machine will begin the engraving or cutting process. Monitor the operation closely. The maximum engraving speed is 600 mm/s.

Image 5.2: The laser engraver in operation, precisely engraving a detailed eagle design onto a wooden surface.

Image 5.3: An illustration of the laser head moving at high speed (600 mm/s) across a wooden surface, demonstrating the machine's operational efficiency.

6. देखभाल

Regular maintenance ensures optimal performance and extends the lifespan of your laser engraver.

- Lens and Mirror Cleaning: Periodically clean the laser lens and mirrors with a specialized lens cleaning solution and cotton swabs. Dust and debris can degrade laser performance.

- पाणी थंड करण्याची व्यवस्था: Regularly check the water level in the cooling reservoir and replenish with distilled water as needed. Replace the water every 1-2 months to prevent algae growth and maintain cooling efficiency.

- Air Assist Nozzle: Inspect and clean the air assist nozzle to ensure unobstructed airflow.

- Workbed Cleaning: Clean the honeycomb workbed to remove accumulated debris and residue.

- स्नेहन: Apply a small amount of lubricant to the guide rails and moving parts as recommended by the manufacturer to ensure smooth operation.

7. समस्या निवारण

हा विभाग तुम्हाला येऊ शकणाऱ्या सामान्य समस्यांबद्दल चर्चा करतो.

| समस्या | संभाव्य कारण | उपाय |

|---|---|---|

| लेझर फायरिंग नाही | Lid open, water flow error, power issue, emergency stop engaged | Ensure lid is closed, check water pump and flow sensor, verify power connections, disengage emergency stop. |

| Poor engraving/cutting quality | Incorrect focus, dirty lens/mirrors, incorrect power/speed settings, material issues | Perform autofocus, clean optics, adjust laser settings in LightBurn, ensure material is flat and suitable. |

| Machine not connecting to computer | Cable issue, driver issue, software settings | Check USB/Ethernet cable, reinstall drivers, verify LightBurn device settings. |

| जास्त धूर/धूर | Inadequate ventilation, material type | Ensure exhaust system is fully functional and properly vented. Use appropriate materials. |

8. तपशील

| वैशिष्ट्य | तपशील |

|---|---|

| मॉडेल | RYGEL-USB0705U5 |

| लेसर प्रकार | CO2 लेसर |

| लेझर पॉवर | 100W |

| कार्यक्षेत्र | १७" x ११" (४२५ मिमी x २७० मिमी) |

| कमाल खोदकाम गती | 600 मिमी/से |

| कमाल कटिंग खोली (लाकूड) | 0.6 इंच (15 मिमी) |

| Pass-Through Doors | Four-way (Front/Back: 32.8"x3.7", Side/Side: 20.4"x0.7") |

| लक्ष केंद्रित करणे | ऑटोफोकस |

| हवाई सहाय्य | अंगभूत |

| कूलिंग सिस्टम | Water Pump (external) |

| डेटा ट्रान्समिशन | USB Cable, Ethernet Cable, USB Flash Drive, Offline |

| सॉफ्टवेअर सुसंगतता | लाइटबर्न |

| उत्पादन परिमाणे | 65 x 34.3 x 36.6 इंच |

| मशीनचे वजन | ६३ पौंड. |

Image 8.1: A visual representation of the OMTech 100W CO2 Laser Engraver with key specifications overlaid, including engraving speed, data transmission methods, pass-through sizes, and machine dimensions.

9. हमी आणि समर्थन

OMTech provides comprehensive support for your laser engraver.

- हमी: The product includes 2 years of comprehensive service. Refer to your purchase documentation for specific terms and conditions.

- तांत्रिक समर्थन: A 24/7 global support team is available for expert assistance, including technical guidance.

- संपर्क माहिती: For support, please refer to the contact details provided with your product documentation or visit the official OMTech webसाइट